Everything About Woodworking Machinery: Maximizing Your Workshops Prospective With the Right Equipment

Woodworking machinery plays a crucial function in any type of workshop, influencing both the quality of job and the effectiveness of the procedure. Choosing the right tools can greatly enhance a woodworker's capabilities. From stationary makers to mobile alternatives, each kind serves a distinct function. Understanding these differences is crucial. Numerous woodworkers neglect important aspects when picking their tools. What considerations should be prioritized to absolutely make the most of workshop capacity?

Recognizing the Different Types of Woodworking Equipment

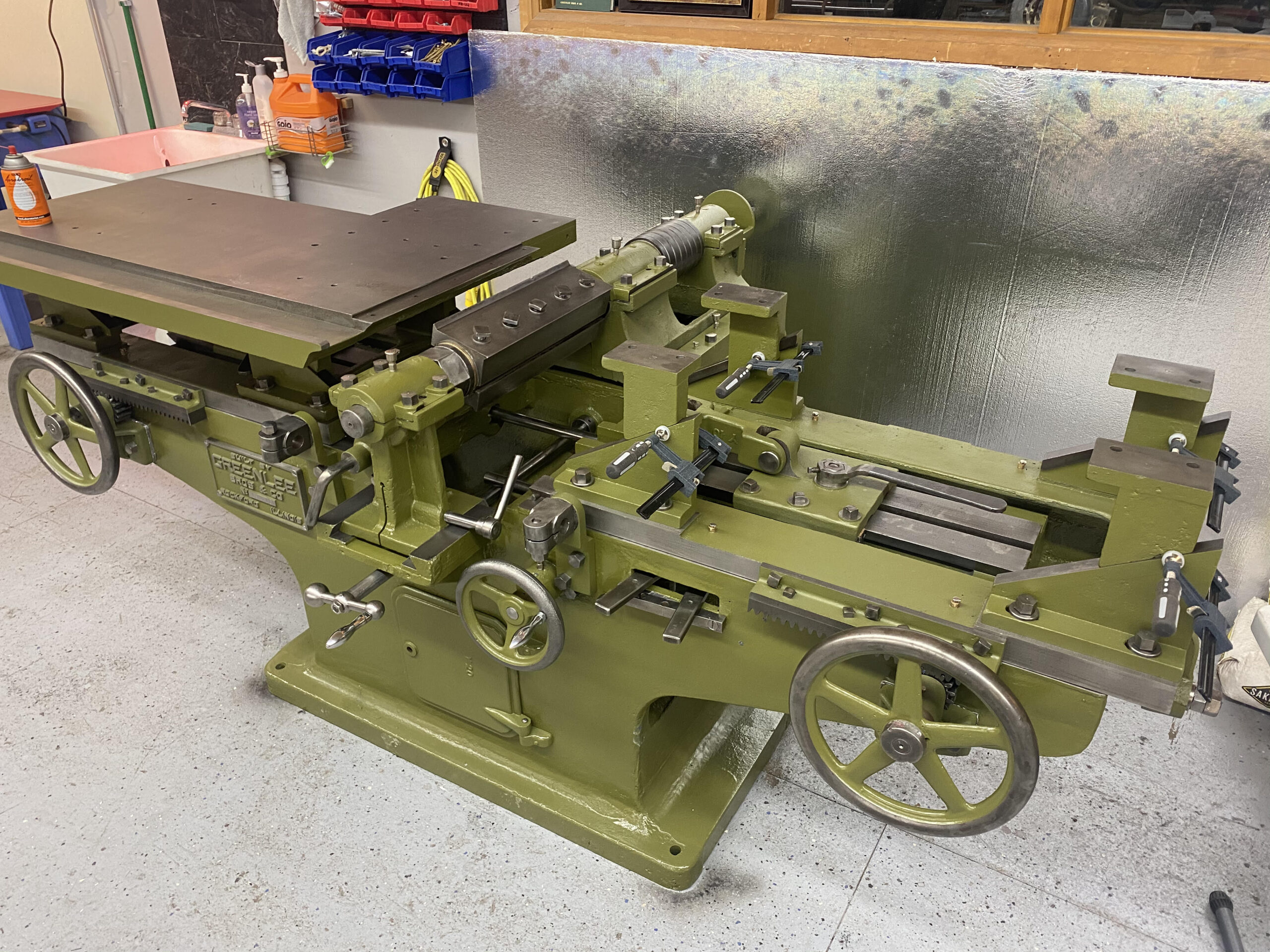

Woodworking machinery encompasses a broad variety of tools, recognizing the different kinds is important for both amateur and expert woodworkers. Numerous categories exist, each created for specific tasks. For instance, stationary devices like table saws, band saws, and jointers supply stability and accuracy for bigger jobs. In contrast, mobile devices such as routers and jigsaws provide adaptability for intricate work and flexibility.

Furthermore, there are customized machines, including lathes and planers, which accommodate certain woodworking methods. Each type serves a distinct objective, contributing to the overall effectiveness and top quality of woodworking endeavors.

Comprehending these differences permits woodworkers to select the right machinery for their projects, guaranteeing perfect results. As they browse their workshop requires, experience with these devices improves ability advancement and task end results, eventually fostering a deeper admiration for the craft of woodworking.

Essential Tools for Every Woodworker

A well-equipped workshop is vital for any kind of woodworker aiming to achieve quality outcomes. Basic tools include a table saw, which gives accuracy cuts for numerous materials, and a miter saw, excellent for tilted cuts in framework and molding. Furthermore, a bandsaw is vital for detailed curves and resawing lumber, while a router permits for decorative sides and joinery job.

Hand devices additionally play an important function; knives, aircrafts, and hand saws provide convenience and control for detailed jobs. A drill press is vital for exact exploration, while a sander helps attain a smooth surface on tasks. Finally, safety equipment, such as safety glasses and ear security, is essential to shield the woodworker throughout operations. By having these crucial tools, a woodworker can enhance their abilities and complete a selection of jobs with self-confidence and performance.

Selecting the Right Equipment for Your Jobs

When choosing devices for woodworking tasks, it is necessary to take into consideration the specific demands of each job to ensure the very best outcomes. Different tasks might demand numerous tools, such as routers, saws, or planers, depending upon the intricacy and products entailed. Complex layouts may benefit from a scroll saw, while larger cuts could call for a table saw for performance and accuracy.

In addition, considering the scale of the job is necessary. Enthusiasts may choose portable tools, while specialist woodworkers often buy robust equipment for high-volume manufacturing. Safety functions and convenience of usage should also play a considerable function in the decision-making process, as they add to an extra efficient and more secure workplace.

Enhancing Accuracy and Performance in Your Workshop

In the search of enhanced precision and performance in woodworking, recognizing important devices is vital. Proper calibration techniques and routine upkeep can substantially influence the accuracy of machinery. By concentrating on these aspects, woodworkers can enhance their workshop efficiency.

Essential Tools Summary

Woodworking machinery works as the backbone of any type of effective workshop, enabling craftsmen to attain impressive accuracy in their projects. Important tools such as table saws, routers, and jointers play an important role in shaping and refining wood materials. Table saws provide accurate and straight cuts, while routers include detailed layouts and accounts to edges. Jointers warranty monotony and straightness, enabling seamless board assembly. Various other critical machines consist of band saws for rounded cuts and drill presses for constant hole placement. Each tool adds to taking full advantage of efficiency, decreasing manual initiative, and improving the general top quality of job. Purchasing these vital woodworking tools is key for any More about the author kind of craftsmen wanting to elevate their craftsmanship and performance in the workshop environment.

Calibration Strategies Clarified

Precise calibration of woodworking machinery is crucial for accomplishing optimal performance and accuracy in projects. This process entails changing tools to assure they run within specified resistances. Strategies for calibration differ based on the kind of machinery but generally include verifying dimensions against requirements and making necessary changes. As an example, table saws call for precise blade placement, while routers may require depth settings fine-tuned. Regularly recalibrating and inspecting machinery not just enhances accuracy however additionally improves performance, reducing the danger of pricey mistakes. Using adjusted measuring tools, such as squares and calipers, can even more ensure that changes are made correctly. Ultimately, constant calibration develops a trustworthy workflow, allowing woodworkers to concentrate on creative thinking and workmanship without compromising high quality.

Upkeep for Accuracy

Maintaining woodworking machinery is essential for achieving precision and effectiveness in any type of workshop. Normal pop over to this site upkeep jobs, such as examination, lubrication, and cleaning, assistance guarantee that equipments operate efficiently and accurately. Dust and particles can collect, impacting efficiency and causing mistakes in cuts. Keeping blades sharp and aligned is important; dull blades can cause inconsistent and tear-out outcomes. In addition, calibrating and checking equipment routinely prevents drift, ensuring that dimensions stay true. Operators needs to additionally keep an eye on for wear and replace parts as essential to prevent larger issues. By focusing on maintenance, woodworkers can boost both the accuracy of their work and the lifespan of their devices, eventually maximizing performance and accomplishing top quality results.

Maintenance Tips for Long Life of Your Machinery

Proper upkeep is vital for extending the life-span of woodworking machinery. Normal cleaning methods and a regular lubrication routine can considerably improve efficiency and reliability. By adhering to these guidelines, operators can ensure their devices continues to be in prime problem for several years to find.

Regular Cleansing Practices

Normal cleaning techniques play a crucial function in expanding the life expectancy and performance of woodworking machinery. Dirt and particles can collect on surface areas, resulting in possible breakdowns and decreased efficiency. Operators should regularly evaluate and clean their devices, making use of a soft brush or compressed air to get rid of sawdust and shavings from intricate locations. Furthermore, it is critical to wipe down surface areas with a damp fabric to prevent rust and rust. Unique attention ought to be provided to the equipment's electrical components, ensuring they continue to be devoid of pollutants. In addition, maintaining a clean work space not just improves equipment efficiency but likewise promotes security, lowering the risk of accidents triggered by mess. Consistent cleaning routines eventually add to smoother procedures and prolonged devices life.

Lubrication Schedule Value

While drivers may concentrate on cleansing their woodworking equipment, disregarding the lubrication timetable can bring about substantial damage in time. Lubrication plays a crucial role in preserving peak performance by reducing rubbing in between relocating parts, which can avoid overheating and damage. A consistent lubrication schedule aids ensure that machinery operates efficiently, improving both performance and durability. Operators needs to speak with the manufacturer's standards to establish certain lubrication intervals and types of oils my review here or oils needed. Furthermore, monitoring lubricating substance levels and inspecting for pollutants can even more protect equipment from unnecessary wear. By focusing on a routine lubrication regimen, drivers can greatly decrease fixing costs and extend the life-span of their devices, inevitably optimizing their workshop's productivity.

Upgrading Your Workshop: When and Just how to Buy New Tools

When is the ideal time to purchase brand-new tools for a woodworking workshop? A woodworker ought to take into consideration updating their tools when they observe constraints in their existing devices that hinder performance or the top quality of their projects. Indicators include frequent repairs, inadequacies, or the inability to carry out desired jobs. Additionally, if a woodworker's skills have actually advanced past the capabilities of their tools, it might be time to spend in new equipment.

Budget plays a significant duty in this choice. Researching devices that offer the ideal worth and long life is important. Prioritizing crucial devices over luxury things can make best use of workshop possibility.

Frequently Asked Questions

Exactly how Do I Safely Operate Woodworking Equipment?

To safely operate woodworking equipment, one have to use suitable personal protective equipment, understand the equipment's handbook, preserve a tidy office, maintain hands free from relocating parts, and always utilize security features provided on the equipment. Lumber Stacker.

What Are the most effective Brands for Woodworking Equipment?

Popular brand names for woodworking equipment consist of Powermatic, Grizzly, Jet, DeWalt, and Bosch. Each brand name is identified for its high quality, sturdiness, and cutting-edge functions, accommodating both experts and enthusiasts in the woodworking community.

Can I Utilize Woodworking Equipment for Other Materials?

Yes, woodworking machinery can frequently be adapted for products like plastics or soft metals. Users should verify compatibility to avoid damages and achieve perfect results, considering each device's specifications and desired function.

Exactly how Do I Take Care Of Machinery-Related Injuries?

To deal with machinery-related injuries, one should quickly stop working, assess the injury, use first help, and seek medical interest if required. Coverage the event and reviewing security methods is essential for preventing future incidents.

What Is the Typical Life-span of Woodworking Devices?

The average life-span of woodworking tools varies commonly, normally varying from five to fifteen years, depending on upkeep, top quality, and usage. Correct care can greatly prolong their capability and efficiency throughout their operational life.

Woodworking equipment incorporates a broad array of tools, comprehending the different types is necessary for both expert and amateur woodworkers - Rotary Claming System. Enthusiasts might decide for mobile tools, while professional woodworkers commonly spend in robust machinery for high-volume manufacturing. In the pursuit of enhanced precision and efficiency in woodworking, recognizing vital tools is important. When is the best time to invest in brand-new tools for a woodworking workshop? The average life expectancy of woodworking tools varies widely, generally ranging from five to fifteen years, depending on usage, top quality, and upkeep